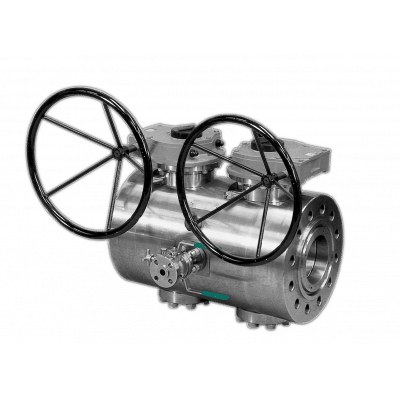

Trunnion ball valves are critical components in various industrial applications, known for their reliability, durability, and precision in regulating the flow of fluids. Manufacturers specializing in trunnion ball valves play a pivotal role in ensuring these valves meet the high standards required for critical applications. Trunnion ball valves are designed with a fixed trunnion a type of support that anchors the ball, allowing it to rotate with minimal friction. This design is particularly advantageous in high-pressure and high-temperature environments. The trunnion ball valve mechanism ensures that the valve can handle large volumes of fluid and sustain the pressure without compromising its functionality.

Oil and Gas Industry – In the oil and gas sector, trunnion ball valves are indispensable for controlling the flow of hydrocarbons through pipelines and processing facilities. The high-pressure environment, coupled with the need for reliable shut-off and flow control, makes trunnion ball valves ideal for this application. They are used in upstream, midstream, and downstream operations, where their ability to provide tight shut-off and withstand harsh conditions is crucial.

Chemical and Petrochemical Plants – The chemical industry demands valves that can handle corrosive and hazardous fluids. Trunnion ball valves, with their robust construction and precise control capabilities, are well-suited for these environments. They ensure safety and efficiency in handling chemicals and petrochemicals, where valve failure could lead to significant operational and safety risks.

Power Generation – In power plants, especially those dealing with steam and high-pressure water, trunnion ball valves are used to manage steam flow, water injection, and other critical processes. Their durability and ability to maintain performance under extreme conditions are vital for the reliability and efficiency of power generation systems.

Water and Wastewater Treatment – Effective water management and wastewater treatment require valves that can handle varying pressures and flow rates. Trunnion ball valves offer the precision needed for these applications, ensuring that water treatment processes run smoothly and efficiently.

Dombor trunnion ball valve manufacturers are integral to the success of these applications. Their value extends beyond merely producing valves it encompasses several key areas:

Quality and Reliability – Manufacturers ensure that trunnion ball valves are built to high-quality standards, capable of withstanding extreme conditions without failure. This involves rigorous testing and adherence to industry standards, ensuring that the valves perform reliably in critical situations.

Customization and Innovation – Different applications have unique requirements, and manufacturers provide customized solutions to meet these needs. They invest in research and development to innovate and improve valve designs, enhancing performance, durability, and safety features.

Technical Expertise – Manufacturers offer valuable technical support and expertise, helping customers select the right valve for their specific application. Their knowledge assists in optimizing valve performance and addressing any operational challenges.

The trunnion ball valve manufacturers are indispensable partners in industries that rely on precise fluid control under challenging conditions. Their commitment to quality, innovation, and customer support enhances the performance and reliability of trunnion ball valves in critical applications. By providing robust and dependable solutions, these manufacturers ensure that vital processes in oil and gas, chemical, power generation, and water treatment sectors can operate smoothly and safely.